About

ACT Gideon sub 9 ppm Ultra Low Nox Burners can be operated (at d, 3% O2):

- NOx ≤ 9 ppm

- CO emissions ≤ 9 ppm

- Excess O2 < 2.5%

- By using FGR.

ACT GIDEON ULTRA LOW NOx BURNER

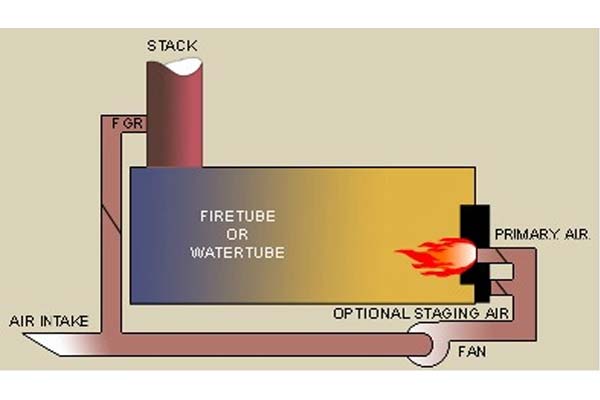

The ACT Gideon Ultra Low NOx Burner is the answer to compliance with emission standards for operators of all boilers. The Burner is a highly precision made Low NOx Burner designed to meet all current and likely future NO emission requirements. The design and operation of the burner is protected by dozens of worldwide patents. Field tests of the burner have demonstrated that the burner can achieve less than 6 ppm NOx (d, 3% O2) without the use of catalyst, reburning or ammonia or urea injection.NEW INSTALLATIONS AND RETROFIT APPLICATIONS

The ACT Gideon Ultra Low NOx Burner can be installed on any new boiler or retrofitted to any existing boiler which uses a forced draft fan. The versatility of the burner is achieved by its simple design and custom manufacture of the connections to the boiler. The burner has been installed on firetube boilers which have swing doors, and watertube boilers without restricting access to the boiler. The custom fit of the burner to the boiler will maintain the original boiler design, allow access to the boiler and minimize the installation cost of the burner.For more informations:

PROJECT SITES

MAINTENANCE

The ACT Gideon Ultra Low NOx Burner is designed for the convenience of the operators of industrial and utility boilers. There are no moving parts in this burner. This simple design reduces maintenance to a minimum.PERFORMANCE & BENEFITS

The ACT Gideon Ultra Low NOx Burner operates with the lowest emissions and the highest performance of available burners. The burner has the following maximun performance characteristics.

- Excess O2 < 1%

- NOx emissions <6 ppm (d,3% O2 )

- CO emissions < 10 ppm (d, 3% O2)

- Compact stable blue flame

- High turndown capability

- No moving part

For more informations:

PERFORMANCE & BENEFITS

* The final guarantee will be based on the final order and proposal.

FEATURE

The burner achieves its outstanding performance by a patented swirl design which produces short, strongly stable flames when using flue gas recirculation, FGR. FGR is provided to the burner through the air fan. FGR is regulated by a damper controlled off the steam demand which is modulated to maintain the optimum ratios of fuel, air and flue gas. The air, FGR and fuel are linked proportionally to maintain proper combustion and the desired levels of O2 , NOx and CO. The burner is fully modulated and has been demonstrated to operate over a high turndown capability.

For more informations: